Epoxy and Polyaspartic Flooring for Commercial and Industrial Applications in Port St. Lucie, FL

Epoxy and Polyaspartic Floor Coatings for commercial and Industrial Applications

Epoxy and polyaspartic flooring solutions are becoming the gold standard for commercial and industrial spaces in Port St. Lucie, FL. With their exceptional durability, versatility, and aesthetic appeal, these flooring systems are designed to withstand the rigorous demands of heavy foot traffic, machinery, and harsh chemicals. Businesses seeking long-lasting and low-maintenance flooring solutions will find that epoxy and polyaspartic floors provide unparalleled performance and value.

Key Benefits of Epoxy and Polyaspartic Flooring

When it comes to flooring solutions for commercial and industrial applications, epoxy and polyaspartic systems stand out for their exceptional performance and versatility. These flooring options not only offer an array of benefits that cater to the specific needs of businesses but also enhance the overall functionality and aesthetic appeal of commercial spaces. Whether you are looking for durability to withstand heavy machinery, cost-effectiveness to maximize your investment, or ease of maintenance to keep operations running smoothly, epoxy and polyaspartic flooring delivers on all fronts. Let’s explore the key advantages that make these flooring systems an ideal choice for your business:

Durability

Epoxy and polyaspartic flooring are engineered to endure the most demanding environments. Their robust composition allows them to resist chipping, cracking, and wear over time. In bustling commercial spaces like warehouses and manufacturing facilities, these floors remain intact under heavy loads, making them a reliable choice for any business.

Cost-Effectiveness

Choosing epoxy or polyaspartic flooring can result in significant long-term savings. While the initial investment may be higher than other flooring options, the longevity and durability of these systems mean fewer repairs and replacements over the years. Moreover, their minimal maintenance requirements further enhance their cost-effectiveness, ensuring a high return on investment.

Ease of Maintenance

Maintaining epoxy and polyaspartic flooring is straightforward, thanks to their smooth, seamless surfaces. Spills, dirt, and grime can be easily wiped away, preventing the buildup of contaminants. This characteristic is especially beneficial in industrial settings, where cleanliness is crucial for safety and compliance.

Reflectivity

One of the standout features of these flooring systems is their high reflectivity. Epoxy and polyaspartic floors can significantly enhance lighting in commercial spaces, reducing the need for excessive artificial lighting. This not only improves visibility but can also lower energy costs, making it an eco-friendly option for businesses.

Customization Options

Epoxy and polyaspartic flooring can be tailored to meet the specific needs of your business. Custom color choices allow you to match your brand's aesthetics, while the incorporation of logos enhances your business identity. Anti-slip finishes can be added for safety, making these floors both functional and visually appealing.

The Installation Process

The installation of epoxy and polyaspartic flooring involves several key steps,

each critical for ensuring the success and longevity of the flooring system:

1. Site Assessment

A comprehensive assessment is conducted to evaluate the current flooring condition. This involves checking for cracks, surface damage, and moisture levels. Understanding the specific environment in Port St. Lucie helps in selecting the most appropriate flooring solution.

2. Surface Preparation

Proper preparation is essential for adhesion and overall performance. This process includes cleaning, grinding, or shot blasting the existing surface to create a profile that promotes bonding. Any existing coatings or sealers must be removed to ensure a clean substrate.

3. Application of Epoxy/Polyaspartic Base Coat

A base coat of epoxy or polyaspartic resin is applied to the prepared surface. This layer serves as a strong foundation, offering enhanced durability and adhesion. It's crucial to apply this coat evenly to avoid imperfections.

4. Incorporation of Custom Elements

At this stage, custom colors, branding logos, and anti-slip additives can be integrated into the flooring system. This allows businesses to create a unique appearance while ensuring safety standards are met.

5. Topcoat Application

A protective topcoat is applied after the base coat has cured. This layer provides additional resistance to chemicals, abrasions, and UV exposure, extending the life of the flooring system. The topcoat is crucial for maintaining the floor's aesthetic and functional properties.

6. Curing Time

The curing time for epoxy and polyaspartic flooring varies, with polyaspartic typically curing faster. This rapid curing time minimizes downtime for businesses, allowing for quicker return to service—a vital consideration for commercial environments where operations must continue uninterrupted.

Recommended Applications

Epoxy and polyaspartic flooring systems are incredibly versatile and can be tailored to meet the specific needs of various commercial and industrial environments. Their unique properties make them ideal for a wide range of applications, ensuring that businesses can find the perfect flooring solution to enhance both functionality and aesthetics. Below are some of the most common applications where these flooring systems excel, showcasing their benefits across different industries:

Warehouses and Distribution Centers

In warehouses and distribution centers, the flooring must withstand significant wear and tear from heavy foot and vehicle traffic. Epoxy and polyaspartic flooring provide an exceptionally durable surface that resists impacts, abrasions, and chemicals commonly found in these settings. Their seamless design prevents dirt and contaminants from accumulating in cracks or seams, which is crucial for maintaining cleanliness and safety. Additionally, the slip-resistant properties of these floors enhance safety for workers navigating busy areas, making them a reliable choice for any warehouse operation.

Manufacturing Facilities

Manufacturing facilities often face exposure to harsh chemicals, heavy machinery, and high foot traffic, making it essential to have a flooring solution that can withstand these challenges. Epoxy and polyaspartic flooring are designed to resist chemical spills, oil, and other contaminants, ensuring that the workspace remains safe and compliant with industry standards. Their durability means that they can endure the stress of heavy equipment without deteriorating, leading to lower maintenance costs over time. Moreover, the reflective surface of these floors improves visibility in manufacturing environments, enhancing worker productivity.

Retail Spaces

For retail environments, aesthetics are just as important as functionality. Epoxy and polyaspartic flooring can be customized with a variety of colors, patterns, and finishes to create a visually appealing shopping experience that aligns with your brand identity. The seamless nature of these floors not only contributes to a modern look but also facilitates easy cleaning, ensuring that the space remains inviting for customers. Additionally, their durability allows them to withstand the high foot traffic typical in retail settings without showing signs of wear, ensuring that your investment remains attractive over the years.

Laboratories and Healthcare Facilities

In laboratories and healthcare facilities, maintaining a sterile environment is paramount. Epoxy flooring's seamless surface prevents bacteria and germs from accumulating, making it easier to comply with health regulations. The non-porous nature of epoxy and polyaspartic flooring systems also makes them resistant to stains and spills, which is vital for maintaining hygiene in sensitive environments. With customizable options for anti-slip finishes, these floors provide safety for staff and patients alike, ensuring peace of mind in settings where safety is critical.

Food and Beverage Industry

The food and beverage industry demands flooring solutions that can withstand spills, cleaning chemicals, and high levels of foot traffic. Epoxy and polyaspartic flooring meets these requirements, offering a non-porous surface that is easy to clean and maintain. Their resistance to moisture and spills helps prevent mold and bacteria growth, ensuring a safe environment for food preparation and service. Additionally, these flooring systems can be tailored with anti-slip surfaces to enhance safety in areas where spills are common, making them ideal for restaurants, kitchens, and food processing facilities.

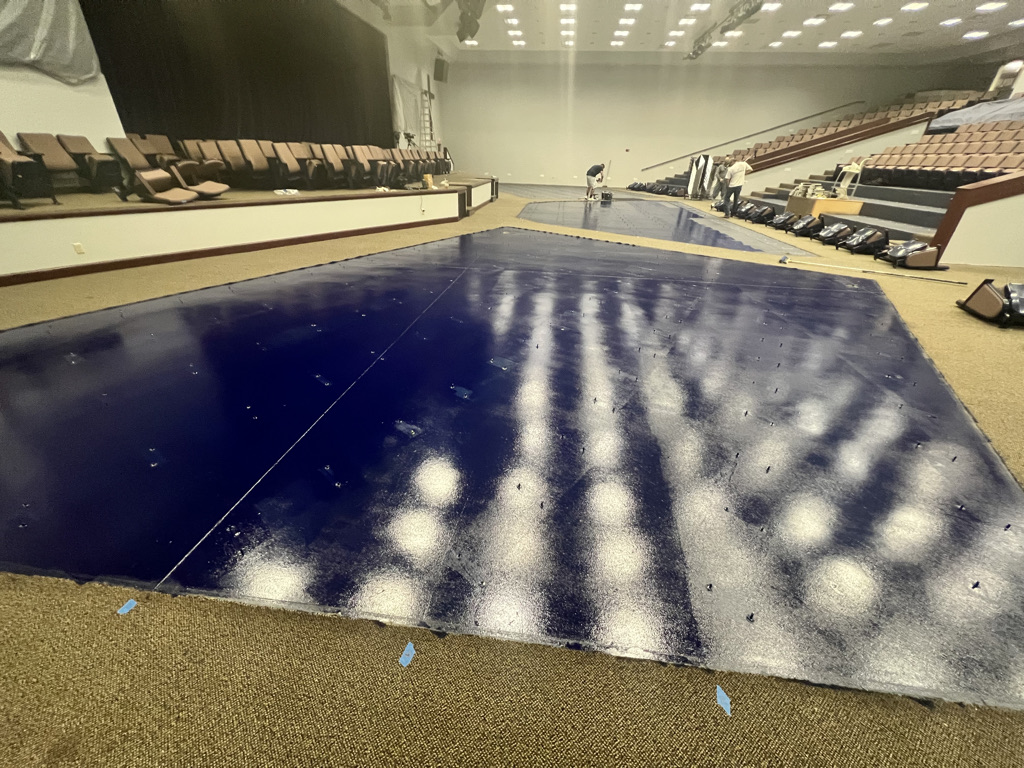

Our Recent Commercial and Industrial Flooring Projects

Showcase of Excellence

At Floor Kings, we take immense pride in our portfolio of successful commercial and industrial flooring projects. Our commitment to quality craftsmanship and attention to detail is evident in every installation we complete. Below, you’ll find a selection of images highlighting our work across various sectors, from warehouses to manufacturing facilities and retail spaces. Each project reflects our dedication to providing durable, aesthetically pleasing flooring solutions that meet the unique needs of our clients in Port St. Lucie, FL. We invite you to explore these examples to see how our epoxy and polyaspartic flooring systems can transform your business environment.

add image slider

The Floor Kings Difference

At Floor Kings, we know how overwhelming it can be to find a reliable and fairly priced flooring contractor. We've all heard the stories—hiring a handyman or an inexperienced crew that promises to cut corners and save you a few dollars, only to disappear once the check clears, leaving you with a subpar floor that won't stand the test of time. That's not how we do business.

flooring is our passion and our sole focus. Whether you're looking for a stunning polished concrete finish for your home, industrial strength epoxy flooring for your warehouse, or a durable concrete coating for a high-traffic area, our expertise is second to none. We don’t just dabble in flooring—we live and breathe it, bringing decades of experience and a commitment to excellence to every project.

Our Expertise, Your Peace of Mind

From residential garages to commercial warehouses and everything in between, we’ve seen and done it all. We specialize in transforming spaces through meticulous craftsmanship, using only top-grade materials designed for longevity. Our team’s experience means that we not only finish jobs on time, but we also ensure they’re done right—the first time. What makes the difference? Preparation.

Quality flooring starts with properly preparing the surface. We go beyond just applying epoxy coatings or polishing concrete; we take the time to prep each substrate carefully, ensuring a flawless, long-lasting result. Whether it’s a driveway, patio, airplane hangar, or commercial kitchen, we treat every project with the same level of dedication and expertise.

Quality Without Compromise

We believe that every customer deserves high-quality flooring without the hassle of inflated prices or unnecessary upsells. From day one, our pricing is transparent —no gimmicks, no fluff. Just honest work at a fair price. We’re upfront because we’ve built this business on trust and repeat customers, and we take that responsibility seriously.

When you choose Floor Kings, you’re not just getting a contractor; you’re getting a partner in your flooring journey. From start to finish, we work to make the process seamless and stress-free, ensuring that you're thrilled with the end result—whether it’s a polished concrete floor that gleams or an epoxy coating tough enough to handle the wear and tear of a busy warehouse.

The Floor Kings Difference

At Floor Kings, we know how overwhelming it can be to find a reliable and fairly priced flooring contractor. We've all heard the stories—hiring a handyman or an inexperienced crew that promises to cut corners and save you a few dollars, only to disappear once the check clears, leaving you with a subpar floor that won't stand the test of time. That's not how we do business.

flooring is our passion and our sole focus. Whether you're looking for a stunning polished concrete finish for your home, industrial strength epoxy flooring for your warehouse, or a durable concrete coating for a high-traffic area, our expertise is second to none. We don’t just dabble in flooring—we live and breathe it, bringing decades of experience and a commitment to excellence to every project.

Our Expertise, Your Peace of Mind

From residential garages to commercial warehouses and everything in between, we’ve seen and done it all. We specialize in transforming spaces through meticulous craftsmanship, using only top-grade materials designed for longevity. Our team’s experience means that we not only finish jobs on time, but we also ensure they’re done right—the first time. What makes the difference? Preparation.

Quality flooring starts with properly preparing the surface. We go beyond just applying epoxy coatings or polishing concrete; we take the time to prep each substrate carefully, ensuring a flawless, long-lasting result. Whether it’s a driveway, patio, airplane hangar, or commercial kitchen, we treat every project with the same level of dedication and expertise.

Quality Without Compromise

We believe that every customer deserves high-quality flooring without the hassle of inflated prices or unnecessary upsells. From day one, our pricing is transparent —no gimmicks, no fluff. Just honest work at a fair price. We’re upfront because we’ve built this business on trust and repeat customers, and we take that responsibility seriously.

When you choose Floor Kings, you’re not just getting a contractor; you’re getting a partner in your flooring journey. From start to finish, we work to make the process seamless and stress-free, ensuring that you're thrilled with the end result—whether it’s a polished concrete floor that gleams or an epoxy coating tough enough to handle the wear and tear of a busy warehouse.

Request Your Free Quote Today

Take the First Step Toward Beautiful Concrete

Ready to give your concrete surfaces a new lease on life? Contact Floor Kings today for a free, no-obligation quote. Our team is standing by to help you explore your options and schedule your resurfacing project. Whether you're refreshing a patio, driveway, or garage floor, we guarantee professional results that last.

Fill out the form below to get started on transforming your concrete:

Call or TXT

Frequently Asked Questions

Have a question that isn't answered on our site? Write us in the chat

What are epoxy and polyaspartic flooring?

Epoxy and polyaspartic flooring are high-performance flooring systems made from durable resins and hardeners. Epoxy flooring consists of a mixture of epoxy resins and polyamine hardeners, creating a tough, chemical-resistant surface ideal for industrial and commercial applications. Polyaspartic flooring is a type of polyurea that offers faster curing times and greater flexibility, making it suitable for environments that require quick turnaround times. Both options provide seamless, non-porous surfaces that resist stains, chemicals, and heavy foot traffic, making them perfect for various commercial settings.

What are the main benefits of using epoxy and polyaspartic flooring in commercial spaces?

The main benefits include durability, cost-effectiveness, ease of maintenance, and customization options. These flooring systems are designed to withstand heavy loads and resist damage from chemicals and spills, making them ideal for warehouses and manufacturing facilities. Additionally, their seamless nature allows for easy cleaning, which is crucial in environments where hygiene is a priority, such as laboratories and food processing areas. Customization options allow businesses to select colors and finishes that align with their branding, enhancing the overall aesthetic of the space.

How long do epoxy and polyaspartic floors last?

Epoxy and polyaspartic floors can last 10 to 20 years or more with proper care and maintenance. Factors that influence their longevity include the quality of the installation, the type of materials used, and the level of foot traffic or equipment usage. Regular cleaning and timely repairs of any minor damages can significantly extend the lifespan of these floors, making them a wise investment for commercial and industrial applications in Port St. Lucie.

Can epoxy and polyaspartic floors withstand heavy machinery?

Yes, epoxy and polyaspartic flooring are engineered to withstand heavy machinery and equipment commonly found in industrial settings. Their robust composition allows them to endure the weight and impact of forklifts, pallet jacks, and other heavy machinery without cracking or chipping. This durability makes them an excellent choice for warehouses, manufacturing facilities, and distribution centers.

How do I maintain epoxy and polyaspartic flooring?

Maintaining epoxy and polyaspartic flooring is relatively straightforward. Regular cleaning involves sweeping or vacuuming to remove dirt and debris, followed by mopping with a mild detergent solution. It’s essential to avoid harsh chemicals that could damage the finish. In addition, periodic inspections for any signs of wear, such as scratches or discoloration, will help catch minor issues before they escalate. By adhering to these maintenance practices, your flooring will remain in excellent condition, especially in high-traffic commercial environments.

Are epoxy and polyaspartic floors slip-resistant?

Yes, epoxy and polyaspartic floors can be formulated to be slip-resistant. Anti-slip additives can be incorporated into the surface during the installation process, providing added safety in areas where spills or moisture are common. This is particularly important for commercial and industrial settings in Port St. Lucie, where worker safety is paramount. Ensuring a slip-resistant surface helps prevent accidents and injuries, contributing to a safer work environment.

What types of industries benefit from epoxy and polyaspartic flooring?

Epoxy and polyaspartic flooring benefit a variety of industries, including:

Manufacturing: Resistant to chemicals and heavy machinery, ideal for factories.

Warehousing: Durable under heavy loads, with easy maintenance and cleaning.

Food and Beverage: Non-porous surfaces that can withstand spills and cleaning chemicals.

Retail: Customizable aesthetics that enhance the shopping experience.

Healthcare: Easy to clean and maintain, promoting hygiene in hospitals and clinics.

In Port St. Lucie, businesses in these sectors are increasingly turning to epoxy and polyaspartic flooring for their unique benefits.

How long does the installation process take?

The installation process for epoxy and polyaspartic flooring typically takes one to three days, depending on the size of the area and the complexity of the project. Factors influencing the timeline include the condition of the existing floor, the type of flooring system being installed, and the curing time required. Polyaspartic flooring, for example, cures more quickly than traditional epoxy, allowing for faster installation and reduced downtime for businesses. It’s crucial to work with a professional installer to ensure a smooth and efficient process.

Is it necessary to prepare the existing floor before installation?

Yes, proper surface preparation is essential before installing epoxy or polyaspartic flooring. This process includes cleaning, repairing any cracks, and possibly grinding or shot-blasting the existing surface to create a profile that promotes adhesion. Adequate preparation ensures that the new flooring system bonds correctly and performs optimally over time, minimizing the risk of peeling or damage.

Are there any environmental concerns with epoxy and polyaspartic flooring?

Modern epoxy and polyaspartic flooring systems are designed with environmental considerations in mind. Many manufacturers offer low-VOC (volatile organic compounds) formulations that minimize harmful emissions during and after installation. Additionally, their durability reduces the need for frequent replacements, contributing to less waste. In Port St. Lucie, choosing environmentally friendly flooring solutions aligns with sustainability goals for businesses aiming to reduce their ecological footprint.

Can I customize the color and finish of epoxy and polyaspartic flooring?

Absolutely! Epoxy and polyaspartic flooring can be fully customized in terms of color, texture, and finish. Businesses can select colors that reflect their branding or create patterns that enhance the aesthetic appeal of their space. Options such as metallic finishes, flake systems, or even company logos can be integrated into the flooring, allowing for a unique and personalized look that stands out in commercial environments.

How do epoxy and polyaspartic flooring compare in terms of cost?

While epoxy flooring is typically less expensive than polyaspartic flooring, both options offer excellent long-term value. The initial installation cost may vary based on the specific requirements of the project, such as surface preparation and customization. However, the durability and low maintenance needs of both flooring types ultimately lead to cost savings over time, especially in high-traffic commercial settings. For businesses in Port St. Lucie, investing in quality flooring can reduce long-term expenses significantly.

Are epoxy and polyaspartic floors resistant to chemicals?

If epoxy or polyaspartic flooring sustains minor damage, such as scratches or scuffs, it can often be repaired with a simple patching process. For more extensive damage, such as deep cracks or peeling, it may require professional restoration. Regular inspections and maintenance can help identify issues early, allowing for prompt repairs that can extend the lifespan of the flooring. In Port St. Lucie, working with a reputable flooring contractor ensures that repairs are handled efficiently and effectively.

Are there any specific building codes or regulations regarding flooring in commercial settings?

Yes, commercial flooring installations must adhere to local building codes and safety regulations. These codes can vary by state and municipality, so it’s essential for business owners in Port St. Lucie to consult with local authorities or a professional flooring contractor to ensure compliance. This may include requirements for slip resistance, fire ratings, and hygiene standards, particularly in industries like food service and healthcare.

What happens if the flooring gets damaged?

If epoxy or polyaspartic flooring sustains minor damage, such as scratches or scuffs, it can often be repaired with a simple patching process. For more extensive damage, such as deep cracks or peeling, it may require professional restoration. Regular inspections and maintenance can help identify issues early, allowing for prompt repairs that can extend the lifespan of the flooring. In Port St. Lucie, working with a reputable flooring contractor ensures that repairs are handled efficiently and effectively.

Can I install epoxy or polyaspartic flooring myself, or should I hire a professional?

While some business owners may consider a DIY installation, it is highly recommended to hire a professional for the best results. Installing epoxy or polyaspartic flooring requires specialized knowledge and experience, particularly regarding surface preparation and application techniques. Professionals can ensure that the flooring is installed correctly, minimizing the risk of future issues and maximizing the lifespan of the flooring system.

How do temperature and humidity affect the installation of epoxy and polyaspartic flooring?

Temperature and humidity levels play a crucial role in the installation and curing of epoxy and polyaspartic flooring. Most products have specific temperature ranges for optimal application and curing, typically between 60°F and 90°F (15°C to 32°C). High humidity can slow curing times, while extremely low temperatures can affect adhesion. It’s essential to monitor environmental conditions during installation to ensure a successful outcome. In Port St. Lucie, where humidity levels can fluctuate, proper planning is key to a successful installation.

Can I use epoxy and polyaspartic flooring outdoors?

Yes, both epoxy and polyaspartic flooring can be used for outdoor applications, provided they are formulated specifically for exterior use. Polyaspartic flooring is particularly well-suited for outdoor environments due to its UV stability, which prevents yellowing and degradation from sunlight exposure. Outdoor applications may include patios, walkways, and loading docks. For businesses in Port St. Lucie considering outdoor installations, selecting the appropriate product is essential for ensuring durability and performance.

How can I be sure I’m getting a quality installation?

To ensure a quality installation, it’s vital to work with a reputable flooring contractor who has experience in commercial and industrial applications. Look for reviews, testimonials, and examples of past work to assess their capabilities. Additionally, ensure that the contractor follows industry best practices for preparation, installation, and curing processes. Open communication about your specific needs and expectations will also help guarantee that you receive a flooring solution that meets your standards.

How does epoxy and polyaspartic flooring improve workplace safety?

Epoxy and polyaspartic flooring can significantly enhance workplace safety in commercial and industrial settings. These flooring systems can be customized with anti-slip additives, reducing the risk of slips and falls, especially in high-traffic areas or locations prone to spills. Their seamless design minimizes the chances of debris accumulation, which can also contribute to safer walking conditions. Additionally, epoxy flooring's high reflectivity improves lighting in the workplace, enhancing visibility and further promoting a safer environment. In Port St. Lucie, where humidity and rain can affect workplace conditions, these flooring options provide a practical solution for maintaining safety.

Frequently Asked Questions

Have a question that isn't answered on our site? Write us in the chat

What is epoxy flooring?

Epoxy flooring is a high-performance surface created by applying a mixture of resin and hardener to concrete floors. When these two components chemically react, they form a rigid plastic material that bonds tightly to the surface. The result is a thick, durable, and seamless coating that is not only visually appealing but also highly resistant to wear and tear. Epoxy flooring is commonly used in industrial settings due to its toughness, but it's also gaining popularity in residential spaces like garages and basements for its glossy finish and customizable designs. Homeowners appreciate epoxy for its ability to transform dull concrete into a sleek, attractive surface.

How long does epoxy flooring last?

Epoxy flooring is known for its impressive lifespan, typically lasting between 5 to 10 years in residential settings with regular care and maintenance. In commercial or industrial environments, where the floors may be exposed to heavier traffic and more challenging conditions, epoxy can still last 2-3 years before requiring touch-ups or a new coat. Factors like foot traffic, exposure to sunlight, and the type of chemicals or oils the floor is exposed to will influence its longevity. Proper maintenance, such as regular cleaning and avoiding harsh chemicals, can extend the life of epoxy floors, helping them maintain their glossy appearance and structural integrity over time.

Can epoxy flooring be used in residential homes?

Yes, epoxy flooring is an excellent choice for residential homes, especially in areas that endure heavy foot traffic or exposure to spills and moisture, such as garages, basements, kitchens, and even laundry rooms. Epoxy is not only durable and resistant to damage but also customizable, available in a range of colors and finishes that allow homeowners to enhance the aesthetic appeal of their space. Homeowners often choose epoxy for its high-gloss finish, which adds a modern, polished look to otherwise plain concrete floors. Additionally, epoxy’s seamless surface makes it easy to clean and maintain, making it practical for family homes.

How should epoxy flooring be maintained?

Maintaining epoxy flooring is straightforward, which is one of the reasons it's such a popular choice for both homes and businesses. To keep your epoxy floor looking its best, start by sweeping or vacuuming regularly to remove dirt and debris. Mop the surface with a mild detergent and water, avoiding harsh or abrasive cleaners that could damage the glossy finish. For tougher stains, a gentle scrubbing with a soft-bristle brush should do the trick. Be cautious of dragging heavy objects across the surface, as this could cause scratches. With proper care, epoxy flooring will maintain its appearance and durability for years to come.

How long does epoxy flooring take to install?

The installation of epoxy flooring typically takes 2-3 days from start to finish, depending on the size and condition of the area. The process begins with thorough cleaning and preparation of the concrete surface, followed by the application of a primer and multiple layers of epoxy. Each layer needs time to cure before the next can be applied, which can take 12 to 24 hours. After the final coat, the epoxy will take an additional 72 hours to fully cure before the floor can handle heavy traffic. Although the process takes time, the result is a long-lasting, durable floor that’s well worth the wait.

Is epoxy flooring slippery?

While epoxy floors are smooth and glossy, they can become slippery when wet, especially in areas prone to spills or moisture, like garages or kitchens. However, there are ways to address this. Anti-slip additives, such as sand or aluminum oxide, can be mixed into the epoxy coating to create a textured surface that improves traction. Additionally, decorative flakes or chips can add both aesthetic value and slip resistance. For homeowners concerned about safety, especially in areas where children or elderly individuals may be walking, incorporating these non-slip elements into the epoxy finish is a practical and effective solution.

Can epoxy flooring be used outdoors?

Epoxy flooring is generally not recommended for outdoor use because it tends to degrade when exposed to direct sunlight over time. The UV rays can cause the epoxy to yellow, fade, and become brittle, reducing its durability. However, for covered outdoor areas like garages, it can still be a viable option. If you're looking for an outdoor flooring solution with similar benefits, polyaspartic coatings may be a better choice, as they are UV-resistant and more suited to withstand outdoor conditions like temperature changes and moisture exposure, all while maintaining their appearance and durability.

Is epoxy flooring heat-resistant?

Yes, epoxy flooring is highly resistant to heat, making it a suitable option for areas that may experience higher temperatures, such as kitchens, workshops, or garages where heat-generating equipment is used. Epoxy can typically withstand temperatures of up to 200°F (93°C) without suffering damage, and certain high-performance epoxies can endure even higher temperatures. However, it's essential to note that prolonged exposure to extreme heat may cause some degradation over time. For spaces where heat exposure is a significant concern, consulting with your installer about heat-resistant epoxy formulations can ensure the floor maintains its integrity and durability.

Can epoxy flooring be repaired?

Yes, minor damage to epoxy flooring, such as small cracks or chips, can be repaired without the need for a complete resurfacing. Repair kits are available that allow homeowners or professionals to fill in damaged areas and apply a fresh coat of epoxy to restore the floor’s seamless appearance. However, extensive damage or widespread wear may require reapplication of the epoxy to maintain a uniform look. Regular maintenance and addressing minor issues as they arise can help prevent the need for larger, more costly repairs. A professional installer can assess the damage and recommend the best course of action.

Is epoxy flooring eco-friendly?

While epoxy is a synthetic material and is not biodegradable, it can still be considered environmentally friendly in certain respects. Epoxy flooring increases the lifespan of concrete floors, reducing the need for frequent replacements, and it requires fewer harsh chemicals for cleaning. Additionally, some epoxy products are now formulated with low-VOC (volatile organic compounds), which means they emit fewer pollutants into the air during installation. For homeowners concerned about the environmental impact, choosing low-VOC epoxy options and practicing responsible maintenance can help reduce its ecological footprint.

What is polyaspartic coating?

Polyaspartic coating is a type of advanced polyurea-based floor coating that offers superior durability and fast curing times. Originally developed for industrial use, polyaspartic coatings have become a popular choice for residential applications due to their resistance to wear, chemicals, and UV light. Unlike traditional epoxy coatings, polyaspartic cures much faster, often within hours, allowing for quicker project completion. Its flexibility makes it suitable for a wide range of environments, from garages and basements to patios and pool decks.

How long does polyaspartic coating take to cure?

Polyaspartic coatings have an extremely fast curing time compared to epoxy. In most cases, they are fully cured within 24 hours, allowing you to resume normal use of the area quickly. In fact, some polyaspartic floors can be walked on within 4-6 hours and driven on in less than a day, depending on environmental conditions. This makes polyaspartic an excellent option for projects where minimal downtime is a priority.

Is polyaspartic coating UV-resistant?

Yes, one of the major advantages of polyaspartic coatings is their superior UV resistance. Unlike epoxy, which can yellow or fade when exposed to direct sunlight over time, polyaspartic coatings maintain their color and finish even in outdoor environments. This makes them an ideal choice for exterior surfaces such as patios, driveways, and pool decks, ensuring long-lasting visual appeal in areas exposed to the sun.

Can polyaspartic coatings be used indoors and outdoors?

Absolutely! Polyaspartic coatings are highly versatile and can be used in both indoor and outdoor applications. Indoors, they are popular for garage floors, basements, and even kitchens due to their durability and aesthetic appeal. Outdoors, polyaspartic is commonly applied to patios, driveways, and pool decks, where its UV resistance and durability help it stand up to weather and high foot traffic. The fast curing time also makes it ideal for projects where outdoor exposure is unavoidable.

Are polyaspartic coatings resistant to chemicals and stains?

Yes, polyaspartic coatings are highly resistant to chemicals, including automotive fluids, cleaning agents, and even harsh industrial chemicals. This makes them a great choice for garages, workshops, and other areas prone to spills. In addition to chemical resistance, polyaspartic coatings are also resistant to stains, ensuring that spills can be easily cleaned up without leaving a mark. Their non-porous nature prevents substances from seeping into the surface, maintaining the floor’s appearance over time.

Your Title Here

Yes, polyaspartic coatings are highly resistant to heat, making them an excellent choice for areas exposed to high temperatures, such as outdoor patios, driveways, and garages. Unlike some flooring materials that may soften or warp under prolonged exposure to heat, polyaspartic coatings maintain their structural integrity and finish even in hot climates. In regions like Port St. Lucie, Florida, where temperatures can rise significantly, polyaspartic coatings provide a durable, UV-resistant solution that won't fade or discolor under the sun. This heat resistance ensures long-term performance in both residential and commercial settings.

What is the maintenance required for polyaspartic flooring?

Polyaspartic flooring is incredibly low-maintenance. Regular sweeping and occasional mopping with a mild detergent are usually sufficient to keep the floor looking new. Thanks to its resistance to scratches, chemicals, and stains, polyaspartic requires less upkeep than other flooring options. Additionally, its seamless finish makes it easy to clean, as there are no grout lines or cracks where dirt can accumulate. It’s a long-lasting solution that minimizes time spent on maintenance.

Can polyaspartic coatings be customized?

Yes, polyaspartic coatings are highly customizable in terms of color, texture, and finish. Homeowners can choose from a wide variety of color options to match the aesthetic of their space. Decorative flakes, metallic finishes, and even custom patterns can be incorporated into the polyaspartic coating to achieve a unique look. This flexibility in design makes polyaspartic coatings ideal for both residential and commercial spaces that require a personalized touch.

Is polyaspartic flooring slip-resistant?

Yes, polyaspartic flooring can be formulated to be slip-resistant, which makes it a safe choice for high-traffic areas, garages, or outdoor spaces like pool decks and patios. During the installation process, an anti-slip additive can be mixed into the coating to provide additional traction, ensuring safety in wet or slick conditions. This feature is especially beneficial in environments where water or other liquids are commonly present.

How durable is polyaspartic compared to epoxy?

Polyaspartic coatings are known for their exceptional durability, often outperforming epoxy in key areas. They are more flexible, which makes them less prone to cracking or peeling, even under heavy use. Additionally, polyaspartic coatings have superior abrasion resistance, making them an excellent choice for high-traffic areas that are exposed to heavy machinery, vehicles, or frequent foot traffic. Their resistance to UV rays, chemicals, and moisture also ensures a longer-lasting finish, making polyaspartic a more durable and versatile option for many homeowners.

Residential

Epoxy/Polyaspartic Flooring

Polished Concrete Flooring

Concrete coating

Concrete Resurfacing

Commercial/Industrial

Epoxy/Polyaspartic Flooring

Polished Concrete Flooring

Concrete coating

Concrete Resurfacing

Contact Us

Blog

About Us

Legal

Floor Kings

Residential

Commercial/Industrial

Areas We Serve:

Vero Beach

Jensen Beach

Hobe Sound

Port Salerno